Recently many providers have questioned whether 3-D manufactured orthotics and prosthetics can be coded in the same way as devices manufactured under current traditional manufacturing? The short answer is yes, but...

Let’s first answer what traditional manufacturing of orthotics/prosthetics is and then subsequently respond to what is meant 3-D manufactured orthotics/prosthetics are.

Traditional manufacturing of custom fabricated orthotics/prosthetics typically involves taking a negative image of the patient’s anatomy and producing a positive model (physical or virtual) of the patient’s anatomy. The manufacturing process then takes mostly raw materials to produce a device made for the one specific patient. This is most often based on either a computer generated carving of the orthotic based on a virtual model. Or manual molding of raw materials against a positive model. They can also be based on using measurements to create a positive model of the patient.

These manufacturing methods are often described as subtractive in nature. That is the manufacturing process uses a great deal of raw material, which is then grinded or otherwise removed from the device. This is most often done to accommodate deformities and other factors in the patient history which the fabricator believes will not be tolerated by the patient. Simultaneously other modifications such as blowing out, bending, and adding other materials can be added to the “raw” device.

Imagine if you will an AFO which requires a bubble patch over the malleolus and expansion to accommodate the navicular tuberosity. The device is manufactured and then the fabricator grinds out or removes (hence subtractive) some of the materials and then replaces the harder material with some soft interface material at either of these sites. See below for a comparable issue with 3D manufacturing.

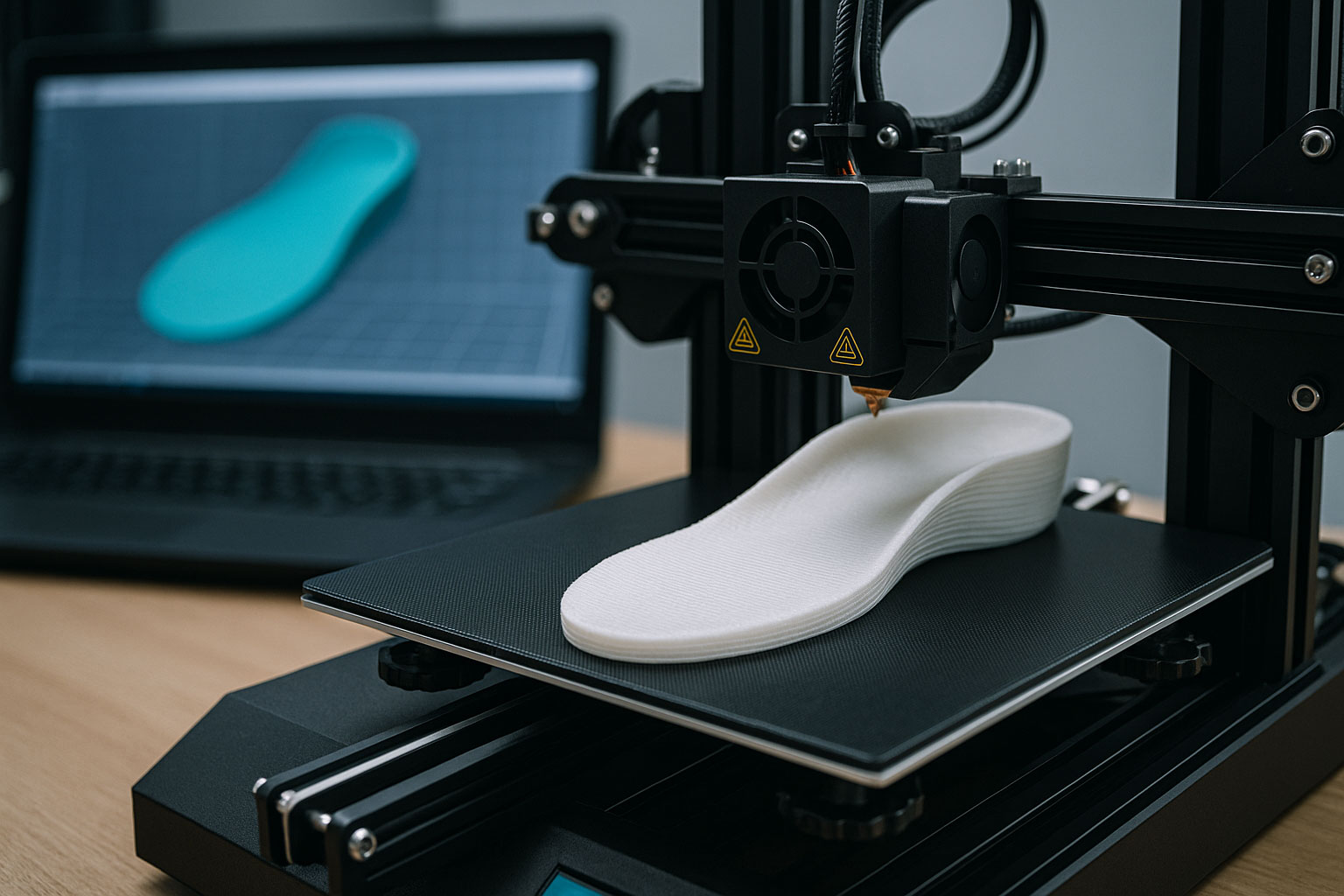

With 3D manufacturing, the digital input would compare the digital virtual model and carefully lay down a layer by layer of materials (same or different durometers) based on the order and virtual model. This allows the manufacture to add and not subtract materials without having to produce and then remove materials. Thus, the manufacturing technique is termed “additive”.

Using the previous example of an AFO produced via 3D manufacturing, the computer would look at the image and the information on the order form. Then the AFO could be produced by using materials of different durometers in a layer-by-layer fashion to specific areas of the device. The ability to produce a device with many nuances, perhaps not possible with the current traditional subtractive process.

Recently, Medicare has published several bulletins addressing the question of 3D produced orthotics and prosthetics. All these bulletins have affirmed that 3D produced orthotics and prosthetics are permitted. Furthermore, they state the HCPCS codes used for the current traditional manufactured orthotics/prosthetics are applicable to those produced by 3D manufacturing.

This is a huge relief to everyone involved in the orthotics and prosthetics industry as well as removing a huge burden on CMS, DME providers and insurance carriers. Can you imagine an entire new set of HCPCS codes having to be approved for 3D produced products vs the current traditional process?

There is however, one minor caveat. That is that the 3D manufacturing process must conform to the Quality Standards Appendix C. These standards are not the same as the Current Supplier Standards.

It would be hard to fathom that any provider reading this bulletin, would not qualify. A future bulletin will further dissect these Quality Standards.

To sum up, orthotics and prosthetics manufactured in additive or 3D fashion, can qualify as custom fabricated, so long as they follow a similar manufacturing process as the current traditional process. That is there is a negative image of the patient’s anatomy, a virtual positive and the device is produced using mostly raw materials either via traditional (subtractive) or additive (3D) produced orthotics.

For more on Quality Standards, read the next future column.